Applicable object: Consignees/Transporters' trucks enter the Terminal for loading imported agricultural cargo.

Consignees/Transporters register the list of vehicles on CICT Portal, included registration number plates, CICT will check and register on Vietnam Registry Department’s website before vehicles arrive in the port. Companies can send vehicles list in advance by email for updating data into CICT system.

Only vehicles with sufficient information can enter the port for loading cargo.

Only 1 driver is allowed to drive the vehicle entering the port. Drivers do not need to disembark and sit in the driving cabin during most of the loading cargo process at port. Drivers only get off at the entrance gate (CICT security staff check vehicles) and at the exit gate (to sign and receive weighing tickets).

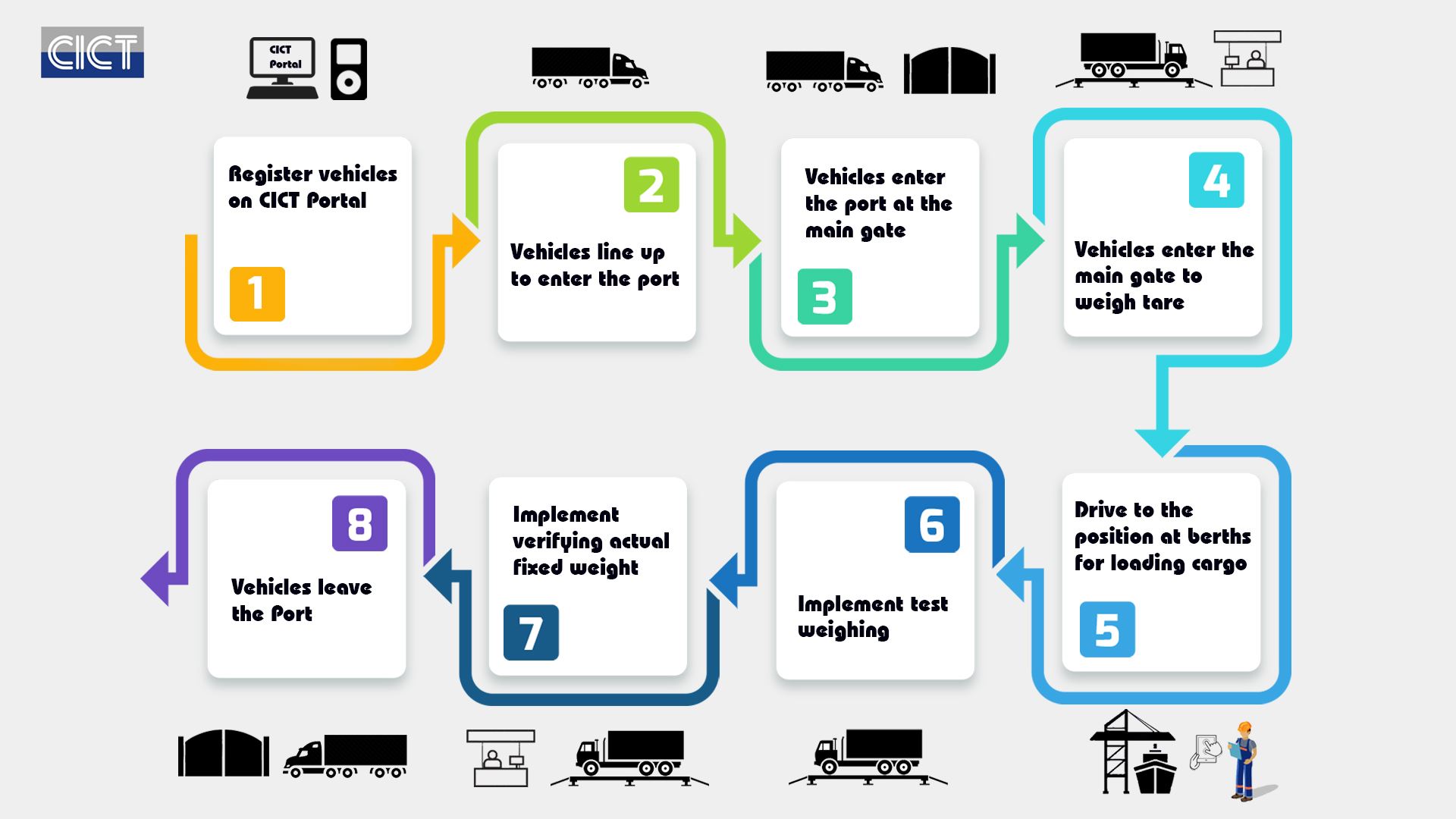

Steps in detail:

Step 1: Register vehicles on CICT Portal

Consignees/Transporters register odd tickers, assign vehicles to blank tickets for vehicles and trailers with valid information. CICT Portal user guide HERE.

Step 2: Vehicles line up to enter the port

When vehicles are driven to the 3-way intersection of the port’s entrance, security staff check and compare the actual license plates and trailer license plates with data on CICT Portal. If it is correct, the vehicles will line up to enter the port, otherwise, vehicles must turn back in line; drivers need to contact consignees/transporters to re-register tickets.

Step 3: Vehicles enter the port at the main gate

At the main gate, security staff implements vehicle security checks as usual but no printing in/out notes. Vehicles are weighed tare after completing checks.

Step 4: Vehicles enter the main gate to weigh tare

When entering tare weight, drivers don’t get off the vehicles. Checker staff weighs according to the plan of consignees registered on CICT Portal. Vehicles are driven to the positions at berths for loading cargo.

Step 5: Vehicles are driven the positions at berths for loading cargo

- At berths, CICT assigns tally staff to instruct drivers to drive vehicles to the crane/hatch position for loading cargo according to the plan.

- Vehicles are driven to the position for loading cargo. Drivers don’t get off the vehicles. CICT assigns staff to discharge cargo from hopper based on actual tare weight and cargo quantity that vehicles are accepted to load onto, according to vehicle registration information.

Step 6: Implement test weighing

Vehicles are driven to overweight control system at yard, which includes weighbridge and suction blower after vehicles are finished loading cargo at berths, CICT suction blower system will do its adjustment task by taking out/ adding on cargo for an ideal weight if vehicles need to add/release more cargo when vehicles are redundant or short of stock.

Step 7: Implement verifying actual fixed weight

Implement verifying fixed weight at the main gate after vehicles are loaded allowable weight of cargo. Drivers don't get off the vehicles.

Step 8: Vehicles leave the port

At the exit gate, drivers get off the vehicles and sign weighing notes to let vehicles out. That ends the process of taking cargo.